HPDI Mystery Filters.

The so called mystery filters are there for a reason and a very good one at that. Removing these filters will shorten the lifespan of the Yamaha High Pressure Direct Injection Pump (HPDI) dramatically and in some instances end it completely.

The older style HPDI pumps were fitted with three of these HPDI mystery filters. Two in the actual pump body and one in the pressure regulator. The new style HPDI pumps are fitted with two “mystery filters” per pump. IE two for a single pump and four for a double pump. Both located in the pump body.

We receive calls on a regular basis asking about the Yamaha HPDI mystery filters and if as mentioned on forums, it is a good idea to remove the filters completely. The answer is simple, replace them with new ones but DO NOT REMOVE THE FILTERS….EVER!

HPDI Fuel Pressure Regulator.

Removing the HPDI mystery filter form the pressure regulator will cause debris to settle on the seat of the pressure regulator valve. This will cause bleed down and the pump will not make pressure. At one thousandths of an inch, the tolerances between the pressure regulator valve shaft and the seat body is very small and debris in this area will cause the pressure regulator valve to get stuck either in the open position and the pump won’t build pressure or in the closed position causing the pump to make too much pressure.

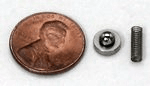

Ball valve and seat.

Each pump unit has two small ball valves that is kept on its seat with a tiny spring. Removing the so called mystery filter form the pump will cause dirt and debris to settle inside the pump on the ball valve seats. Since the ball valve assemblies are so small and the tolerances so tight it does not take much to cause the ball not to seat properly on the seat.

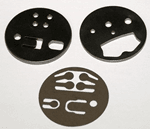

HPDI Reed Valve.

The “Reed valve” plate is housed between two other plates. It is bidirectional thus controlling both intake and outlet. The reed plates make a metal to metal seal and has to be kept clean of debris at all times. Debris inside this area of the pump will cause the reeds not to seat properly thus causing bleed down of the pump.

Pump Bellows, Piston and Sleeve.

The pump piston and shaft assembly is made of stainless steel, whereas the pump sleeve is made of a type of cast iron. Debris logging between the piston and sleeve will cause premature and severe wear and dramatically shorten the pumps live.

Water, when entering the pump will cause the sleeve to rust. This in turn causes the piston to get stuck in the sleeve and render the HPDI pump useless.

Keep in mind that none of the parts are available for purchase from either Yamaha or in the aftermarket. Damage to any one of these parts will render the HPDI pump worthless.

Yamaha HPDI Service.

To keep your Yamaha HPDI pump in good working order and extend the lifespan of the pump considerably send it to us for maintenance.

We don’t just remove and replace the “mystery filters”. We disassemble the pump completely. Thoroughly inspect the internals, component by component . Then clean the pump body and all relevant components ultrasonically. We hand-lap those components that does require so. If all components are clean and meet specification we reassemble and when assembly is complete we test to make sure that your Yamaha High Pressure Direct Injection Pump is working as it is supposed to do.

Since 2006 we have maintained a 24 – 48 hr turnaround time. In the unusual event that your pump may take longer to complete we will contact you to discuss.

If you have any questions, do not hesitate call us from 8 am – 6 pm Central Time at 1.800.381.2065.

Try us, we do not take your business for granted and we are more than willing to earn it!

Want to send your HPDI pump to us for service?