- 800-381-2065

- [email protected]

- 9627 Southwest Freeway, Houston, TX 77074

- Monday – Friday: 8 AM – 4 PM (Central)

Current Turnaround Times

Standard Service – 3-4 Business Days

Expedited Service – 1 Business Day

Last Updated 1/5/2026 at 9:45AM

Standard Service – 3-4 Business Days

Expedited Service – 1 Business Day

Last Updated 1/5/2026 at 9:45AM

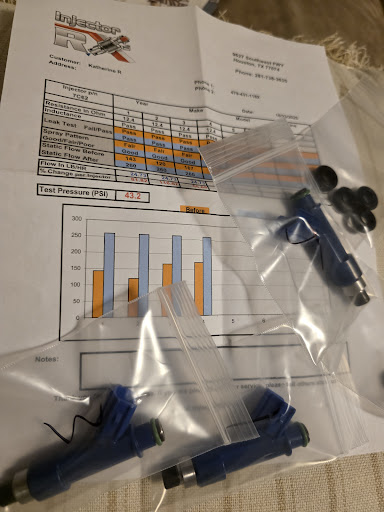

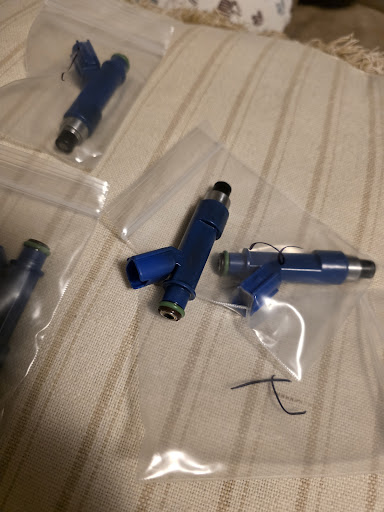

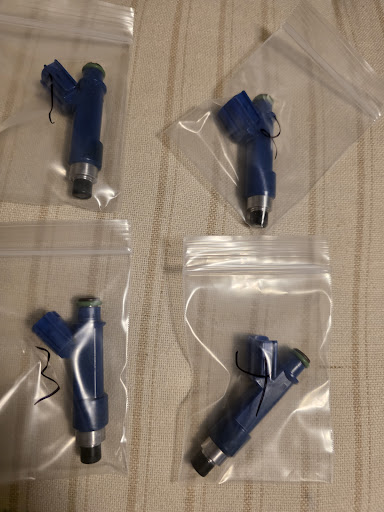

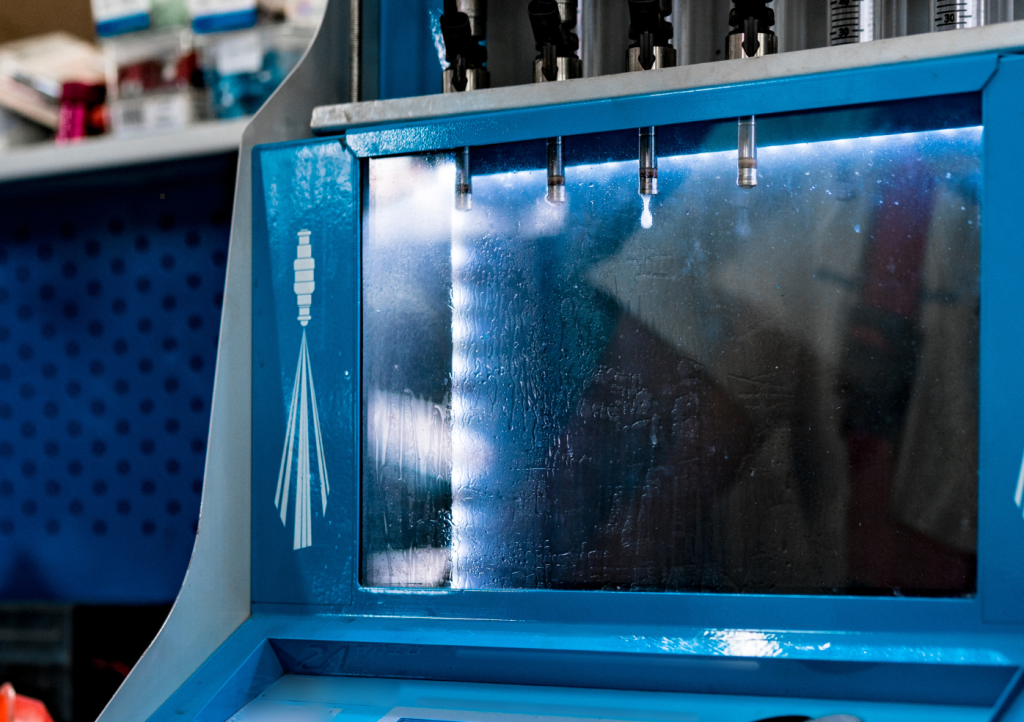

Starting at $22.00 per manifold injector or $30.00 per direct injector, we service, flow-test and restore your gummed up, clogged, dirty or leaking injectors to operate like new. Why pay 4 – 16 times more for a new injector or 3+ times the amount for remanufactured fuel injectors when you can simply restore your current injectors to like-new condition? We will save you money with our OEM-approved ultrasonic fuel injector cleaning and flow testing process. Best of all, we guarantee our work! If we cannot restore your fuel injectors to function like new, you will not be charged for the time spent on those injectors we were unable to clean.

We do not serve diesel injectors or spider assembly injectors.

Experiencing rough idling, poor fuel economy, or engine misfires? These could be symptoms of bad fuel injectors. Learn about common fuel injector problems, their causes, and how to get them fixed.

What are the best methods of cleaning fuel injectors? Do fuel additives really work? How do InjectorRX’s proprietary ultrasonic cleaning and flow testing process compare to DIY cleaning methods?

Make sure your fuel injectors deliver the correct amount of fuel, estimate the maximum horsepower your injectors can support, and more with our free web-based calculators.

Concerned about the safety of shipping your injectors, fuel rail, or fuel pump to our workshop? Learn to prepare your injectors for safe shipping to InjectorRX with our easy-to-follow instructions.