We have been cleaning and flow testing Optimax air injectors and fuel injectors for many years. In doing so we have saved our customers thousand of dollars. Our fuel injector cleaning service and flow testing is used by many dealers.

Optimax Air Injectors and Fuel Injector Problems:

Maintenance and fuel related issues are the main cause for engine performance problems on the Optimax engines.

- Ethanol is hygroscopic and draws water. The combination of water and ethanol damage some fuel lines and cause the internals of both the air and fuel injector to have a residue buildup

- Residue buildup and corrosion of the aluminum fuel rails

- Damaged fuel lines becomes soft and collapse causing fuel flow restrictions.

- Bad Tracker Valve

- Bad Fuel Pressure regulator

- Bad or leaking Schrader valves

- The byproduct of phase separation has a devastating affect on both the air and fuel injectors and will ruin the fuel pump very quickly.

- Clogged fuel injectors due to dirt and phase separation.

Simple Maintenance Recommendations:

- We recommend replacing tank-to-engine fuel lines every year.

- Once fuel related problems occurred we also recommend cleaning both fuel injector and air injectors once a year. Its cheaper than to rebuild an engine due to fuel related problems

- Replace the Air compressor drive belt after every 100 -150 hrs of engine operation

- If a boat setup for more than 6 – 9 months we recommend replacing all filters, clean the air injectors and fuel injectors as well as the rest of the fuel system.

- Beware of using fuel injection cleaners. They might cause more harm than good when you already experiencing problems

Basic operation of the Optimax Air and Fuel System

The Optimax air and fuel injection system is fairly complicated. Not only does it have to supply the exact amount of metered air and fuel but it also has to supply the correct amount of oil to lubricate both bearings and cylinder walls. All three these systems are separate but has to work together to achieve optimum engine performance

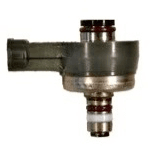

A belt driven air compressor supply air to the lower section of the fuel rail. Better known as the air rail. Fuel is supplied via the top part of the same rail. The fuel injectors are situated directly above the air injectors.Fuel is injected into the air injector. The fuel air mixture is then injected directly into the combustion chamber where it is ignited at a specific timing event to produce optimum power. Dirt in either the air or the fuel system can reap havoc and it is therefore important to keep the system as clean as possible.

There is a 10 Psi difference between the fuel rail pressure and the air rail pressure. The Tracker Valve and Fuel Pressure Regulator maintains exact and fuel pressures. This pressure difference is maintained. If this pressure difference is not maintained you can expect poor engine performance and sometimes the engine will not run at all.

Optimax Air Compressor:

A failed Mercury Optimax air compressor will send debris to the air injectors. This debris can limit the operation of these injectors and cause all kind of performance issue. It is therefore recommended that you have the Optimax air and fuel injectors at least flow tested and if needed cleaned in the event of an air compressor failure.

Optimax air injectors and Fuel Pressure specifications.

Fuel Pressure measured at Starboard Rail Schrader: 88-92 PSI.

Air Pressure measured at Port Rail Schrader: 78-82 PSI.