Our GDI or direct injection fuel injector cleaning includes before and after results and comes with a written report.

2021 Update: We can now replace the Teflon seals on direct injectors for $10 per seal.

| Standard Service: | $30.00 per injector | |

| +$10 per Teflon Seal, optional | ||

| Currently a 5-8 Business Day Turn-Around | ||

| Expedited Service: | $35.00 per injector | |

| +$10 per Teflon Seal, optional | ||

| 1 Business Day Turn-Around |

Or call us today at 1.800.381.2065 for more information. We can clean your direct injectors and save you money! We service injectors for people nationwide!

Engine manufacturers are switching to Direct Injection to meet emissions standards, better performance and greater fuel economy. GDI or Gasoline Direct Injection is the way forward.

What is Direct Injection

Instead of delivering the fuel via an injector in the intake track before the intake valve, GDI or gasoline direct injected engines inject a very fine mist of fuel directly in to the combustion chamber hence the name Direct Injection. Direct injectors operate at fuel pressures that vary between 450 — 3000 Psi. To achieve these pressures, the gasoline is pressurized by a high pressure fuel pump that is mechanically driven and electronically controlled.

Although Optimax air injectors as well as E-Tec and Ficht injectors are considered direct injectors they operate at much lower fuel pressures. Optimax air injector injects both air and fuel at the same time into the cylinder

Why use Gasoline Direct Fuel Injectors?

GDI or Gasoline Direct Injection enables the engine to operate at a stratified charge combustion, described by most of the vehicle manufacturers as an Ultra Lean Burn mode, giving a much improved fuel efficiency, great engine torque and reduced Exhaust Emission levels at low load.

With the sequential firing GDI systems, the injectors only opens to a maximum of 7mS. As the fuel requirement increases, the injector remains at 7mS and the pump pressure increases to meet the demand, allowing the injector to open and close quickly and efficiently. No more “Duty Cycle” as we have known it. These engines use expensive high specification injectors, with Hitachi, Bosch, Denso and Siemens being the major suppliers.

Direct Injection and Carbon Buildup!

Direct injectors are prone to carbon build up and are affected by the hostile environment in the combustion chamber as well as ethanol, hydrocarbons and additives which forms part of today’s fuels.

Because there is no cleaning agent, such as gasoline, present to clean the valves from any debris the current drawback from direct injection systems in 4 cycle engines is the buildup of carbon and dirt behind the intake valves and ports . Engines start losing performance after 45000 miles and the only remedy on some models is costly because it requires removal of the cylinder head to remove the dirt buildup from the intake valves and ports. Newer models such as the Subaru BRZ now make use of both direct injection and manifold injection to curb some of these problems. Another work around is to route the engine breather through an oil catch can.

The importance of direct injection fuel injector cleaning.

GDI Fuel Distribution and Atomization

Fuel Distribution and Atomization is equally critical to the engine’s performance, fuel economy and emission outputs. A clogged direct injector or a set of dirty direct fuel injectors will cause a range of problems and in some instances even severe engine damage.

Our testing equipment allows us to critically examine direct injectors for correct electronic operation in response to changes in mS, RPM and proper atomization as well as the proper cleaning techniques that will allow us to restore your GDI injectors to original specification.

Most direct injection fuel injectors are difficult and time consuming to remove and re-fit; would you fit a set of injectors without ensuring they are working correctly?

Insist your dealer/mechanic/technician send your dirty clogged or leaking direct fuel injectors to Injector RX for cleaning. New direct injectors are expensive. If the injector does not perform up to spec or we can not clean them, we will not charge you for the time spent on that injector. You will only be be responsible for return shipping.

Why flow testing direct injectors at 72.5 psi or 5 Bar

Many customers want to know why we do not test direct injectors at operating pressure.

- It is dangerous

- The equipment is very expensive

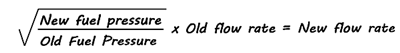

- We can determine flow rate at lower pressure by applying math.

- We can determine and develop a good understanding of spray pattern and atomization at lower pressures

- Spray patterns can be observed much clearer.

Direct injection fuel injector manufacturers usually will supply test pressure in MPa (Megapascal) and the flow rate in g/s (Grams per second)

1 MPa = 10 Bar = 145.0377 psi

1g/s = 7.937 lb/hr

1 lb/hr = 10.5 cc/min

A manufacturers direct injector has the following specification: @ 20 MPa delivering 24 g/s. This means that.

Up to 24 g/s of fuel will be delivered at an operating pressure of 20 MPa and in layman’s terms this means that:

24 x 7.937 = 190.48 lb/hr of fuel will be delivered at a pressure of 20 x 145.0377 = 2900.75 psi.

= 190.48 lb/hr@ 2900.75 psi

To calculate the amount of fuel the direct injector will flow at 72.5 psi, we will use the following calculation:

=√(72.5÷2900.75) x 190.48

= 0.1581 x 190.48

= 30.1148 lb/ hr

Now that we have determined the amount the injector should flow at 72.5 psi we can proceed with the flow testing and measure the testing result against the calculated result.

Acronyms associated with Direct Injectors

GDI = Gasoline Direct Injection (Mitsubishi GDI) Also used on Yamaha HPDI systems

FSI = Fuel Stratified Injection (VW)

SCi = Smart Charge injection (Ford)

HPi = High Precision Injection (BMW)

JTS = Jet Thrust Stoichiometric (Alfa Romeo)

GTDI = Gasoline Turbocharged Direct Injection (Ford)

IDE = Injection Direct Essence

SIDI = Spark Ignition Direct Injection (Holden)

Currently we are not aware of any motorcycles that use direct injection systems.

Or call us today at 1.800.381.2065 for more information. We perform reliable ultrasonic direct injection fuel injector cleaning and truly save you money! We service direct injectors for people nationwide!

Note: Due to cost we currently do not replace some of the O-rings on most of the GDI injectors we service.

Note: Due to liability we do not return used crush washers that some direct fuel injectors use to seal between the cylinder head and fuel injector. These crush washers are a one time use item only.