- 800-381-2065

- [email protected]

- 9627 Southwest Freeway, Houston, TX 77074

- Monday – Friday: 8 AM – 4 PM (Central)

Current Turnaround Times

Standard Service – 3-4 Business Days

Expedited Service – 1 Business Day

Last Updated 2/9/2026 at 11:31AM

Standard Service – 3-4 Business Days

Expedited Service – 1 Business Day

Last Updated 2/9/2026 at 11:31AM

Clogged fuel injectors can severely impact engine performance, preventing fuel from flowing properly and leading to rough idling, poor fuel economy, and even engine failure. Unlike dirty injectors, which restrict fuel flow, clogged injectors completely block fuel delivery, making diagnosis and repair essential. This guide covers common symptoms of clogged fuel injectors, step-by-step diagnostic methods, and the most effective solutions—including ultrasonic fuel injector cleaning. If your engine is running rough, misfiring, or struggling to start, understanding the causes and proper cleaning techniques can help restore performance and efficiency. Keep reading to learn how to diagnose and fix clogged fuel injectors the right way.

More In This Section

Think your injectors are clogged? We can help!

Diagnosing dead or clogged fuel injectors is difficult because it acts the same as a bad coil, dead spark plug, broken spark plug wires and/or electrical problems. Follow these steps for the best results. If you are still unable to diagnose your injectors, we can help! Send them to us and we can report back with our findings and have them back in your hands in less than a week.

Start the Engine Cold

Let the engine idle for 5–10 seconds.

Check Exhaust Manifold Temperature

Carefully touch each exhaust manifold to find the one that’s not warm. If the engine is too hot, you can use water droplets instead.

Disconnect the Injector Connector

Remove the connector from the injector of the cold cylinder.

Inspect the Injector Connector

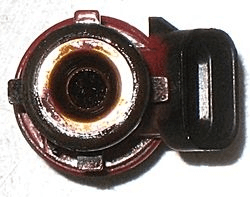

Check for corrosion or damage on the terminals. If visual corrosion or damage is present, there may be poor electrical connectivity, which can lead to injector malfunction.

Test for Power at the Connector

Use an ohm meter or Noid light to verify power supply. If you detect weak or low power coming from the supply, the issue could be with the power supply rather than the injector.

Check Injector Resistance

Use an ohm meter to confirm the injector has the correct resistance according to the manufacturer’s specifications. (Or use our guide here.)

Reconnect the Injector

If no issues are found in the first 6 steps, then we have confirmed that the injector is receiving power, has proper resistance, and is likely not clogged due to corrosion or damage. However, clogs could still exist in the internal components of the injector. Reconnect the injector before moving to step 8.

Listen for Injector Clicks

If diagnostic tools are unavailable, use a stethoscope or rubber hose to listen for clicking sounds from the injector. Position the stethoscope or hose against the fuel injector body and start the vehicle’s engine. You can also rev the engine slightly, if needed. If you don’t hear clicking, this means your injector is not opening and closing properly, which could be caused by a clog or other issue.

Test the Spark Plug

Turn the engine back off and remove the spark plug. If it’s dry and does not smell of gasoline, the injector is likely clogged. If it’s wet with fuel and smells of gasoline, the issue lies elsewhere.

Moving the suspected injector to another cylinder is one way of diagnosing the problem. If the problem moves with the injector then Bingo. Unfortunately, on some engines, this can take hours to do.

If a vehicle, watercraft, motorcycle or pleasure craft sat for an extended period with gasoline in the tank, it can be assumed that the fuel system is gummed up with bad fuel, varnish and sediment. In a situation like this the entire fuel system has to be cleaned. (Yes, we can clean your fuel rails, too!)

Fuel injectors become clogged due to hydrocarbons, sediment and other elements in the fuel. Most fuels contain ethanol. Ethanol is hygroscopic thus drawing moisture from the air into the fuel. The water in the fuel cause internal components to rust. Residue from the rust gets into the injectors when the fuel filter is in bad shape.

Some smaller and older service stations has debris and sediment in their storage tanks and that sediment and debris which eventually can make its way to the injectors is pumped into the fuel tank. Injectors also get gummed up with varnish and gunk which formed when fuel is left in the tank for long periods of time.

Although there are many products such as injection cleaning additives that claim it can clean or unclog a clogged fuel injector while it is in the engine, they cannot. For any of these products to work they actually have to get inside the injector. Common sense predicts that if you cannot get inside something, you are not going to be able to clean it.

By adding fuel injector cleaners to the fuel, the problem will most probably be exacerbated. Why? The injector cleaner has a cleaning affect on everything it touches. All the debris loosened by the cleaner is pumped to the fuel injector set that already has a problem. This makes the problem worse because more debris is pushed into the injectors or the pathway to the injectors. To unclog a clogged fuel injector properly the filter basket must be removed. Sediment and dirt built up between the pintle shaft and injector body must be cleaned. Once it is verified that the injector is completely clean, new filter baskets can now be installed.

The only guaranteed way to unclog a clogged injector properly is by removing the injectors from the engine. Once removed, the injectors can be dropped off or mailed to a professional injector cleaning service such as Injector RX. Injector RX uses manufacturer approved equipment and an ultrasonic fuel injector cleaning process to clean fuel injectors. Once cleaned, the fuel injectors are flow tested to confirm that they spray correctly and deliver the right amount of fuel. The advantages of this method is that it allows Injector RX to fully clean each injector, replace worn parts with new ones, and test each injector for fuel flow comparison.

Let us help you save money and time. Before you decide what to do we strongly suggest you first read this article on the various fuel injector cleaning methods.

A dead fuel injector is an injector that does not have resistance and does not respond to electrical input. They act the same as a clogged injector.

Dead fuel injectors cannot be repaired and should be replaced with the exact same unit.

The good news? We will never charge you for bad injectors. If you send us your fuel injectors and we determine they are unable to be cleaned, serviced, or restored, we will send it back to you without charging you a dime for our service.

Services start at just $12 for flow testing and $22 for cleaning.

It should be noted that all of the above information is the same for marine and motorcycle fuel injection systems and injectors.